Not all factories are guaranteed to pass the Fluke test De Fai Cable FLUKE 90m permanent link as standard

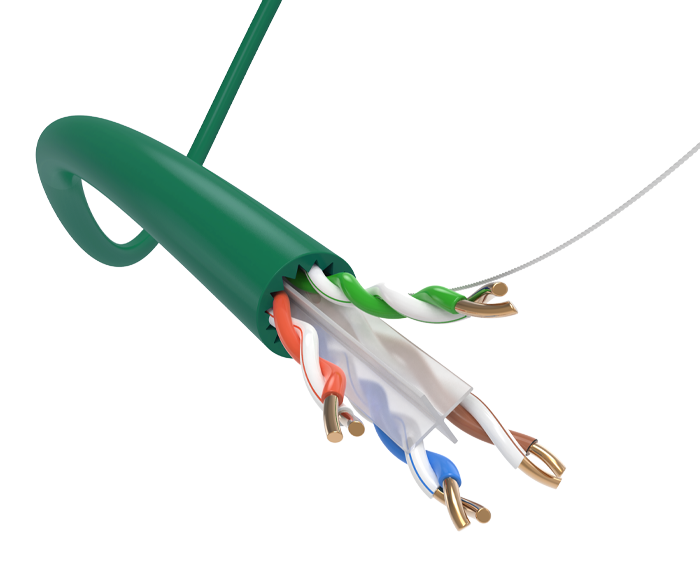

Oil-filled Cable

Explore DLAY CAT6A Cable Solutions

DLAY provides a comprehensive selection of CAT6A bulk cables designed to cater to different networking environments and installation requirements:

CAT6A UTP cables are ideal for low-interference environments, providing reliable data transmission without the need for additional shielding. These cost-effective cables are perfect for residential and standard office setups.

Featuring a protective aluminum foil layer, CAT6A FTP cables minimize electromagnetic interference, making them a dependable choice for environments with moderate noise from electronic devices.

Designed for maximum protection, CAT6A SFTP cables combine foil and braid shielding to prevent signal loss and interference. They are the best solution for industrial and high-performance applications.

Advantages of Oil-Filled Cables

Oil-filled cables offer numerous advantages that make them an excellent choice for high-voltage power transmission and distribution. Here are the key benefits:

● High Insulation Strength:The oil used in these cables provides superior dielectric properties compared to traditional solid insulation materials, allowing them to withstand higher electric stress levels without breakdown.

● Excellent Cooling Properties:Oil effectively dissipates heat generated during operation, preventing hotspots and ensuring that the cable operates within safe temperature limits. This cooling capability is crucial for maintaining performance in high-voltage applications.

● Compact Size and Weight: Due to the reduced thickness of insulation required, oil-filled cables are generally smaller and lighter than solid-filled alternatives. This makes them easier to handle and install in various environments.

● Long Operational Life:With proper design and maintenance, oil-filled cables can have a service life of several decades, making them a reliable solution for long-term infrastructure needs.

● Elimination of Voids:The pressurized oil within the cable prevents the formation of voids, which can lead to electrical failures. This ensures consistent performance and reduces the risk of faults.

● Reduced Capacitance: Oil-filled cables typically exhibit lower capacitance compared to other cable types, which helps minimize charging currents and enhances overall efficiency.

● Resistance to Environmental Factors: The oil insulation protects against moisture, pollutants, and other environmental elements, thereby extending the operational reliability of the cables.

● Enhanced Safety Features:In case of any defects in the lead sheath, oil leakage can be detected early, allowing for proactive maintenance before an earth fault occurs. This feature significantly increases safety during operation.

Customizable CAT6A Cable Solutions

At Guangdong DLAY Cable Technology Co., Ltd., we offer a range of customizable options for our CAT6A bulk cables to ensure they meet the specific requirements of your project:

● Custom Lengths

Our CAT6A cables can be ordered in various lengths, so you only purchase what you need, reducing waste and optimizing cost efficiency.

● Color Variations

Choose from a wide selection of colors—blue, grey, red, green, white, and yellow—making it easy to identify and organize cables during installation.

● Jacket Options

We provide several jacket types, including CMR (Riser Rated), CMP (Plenum Rated), and PVC, offering flexibility for different installation environments such as in-wall, in-ceiling, or for general use.

Technical Specifications

Our oil-filled cables meet the highest industry standards. Key specifications include:

● Voltage Ratings: Up to 170 kV

● Temperature Range: -40°C to +90°C

● Insulation Type: High-quality dielectric oil

Construction: Robust outer sheath for added protection against environmental factors

Why Choose Our Oil-Filled Cables?

DLAY specializes in both bulk production and custom solutions for armored cables. Our robust production capabilities and commitment to quality allow us to meet the diverse needs of our clients across industries.

● Competitive Pricing: By providing direct factory-to-client sales, DLAY offers competitive prices without compromising on quality. We ensure cost-effective solutions for large-scale and small orders alike.

● Large Production Capacity: With a monthly production capacity of over 30,000 cases, we can fulfill both large and small orders efficiently. Our advanced manufacturing processes and well-equipped facilities ensure timely delivery without sacrificing quality.

● Guaranteed Quality: All of our armored cables undergo rigorous testing, including network analyzer and FLUKE tests, to ensure they meet the highest performance standards. We also provide pre-shipment inspection to guarantee the product’s reliability and compliance with global standards.

● Custom Solutions: DLAY understands that every project is unique. We offer tailored solutions, allowing clients to customize cable lengths, materials, and additional features. Whether you need a standard product or a specialized design, we have the expertise to deliver.

Our Advanced Production Equipment

At DLAY Cable, we employ cutting-edge machinery designed for maximum efficiency, precision, and quality assurance. Our state-of-the-art equipment undergoes rigorous maintenance and testing, ensuring each cable meets the highest international standards and consistently exceeds customer expectations.

Production Capacity & Company Scale

Occupying a 7,000-square-meter facility with a free processing setup, we have the spatial and operational flexibility to accommodate varying production demands.

With a monthly output surpassing 30,000 cases, DLAY Cable ensures a steady and reliable supply, meeting the needs of both large-scale and smaller orders.

Production Capacity & Company Scale

We strictly select high-purity copper and top-grade insulation materials compliant with international standards, laying a solid foundation for superior-quality cables.

Using high-precision drawing equipment, the conductor is refined to the specified dimensions and uniformity, ensuring excellent conductivity.

Advanced extrusion techniques apply durable insulation and sheathing layers evenly, ensuring long-term stability throughout the cable’s operational life.

Our precise stranding operations ensure a tightly bonded internal cable structure, enhancing signal transmission quality and mechanical strength.

Every cable undergoes stringent quality testing and inspection before leaving the factory, guaranteeing full compliance with international standards.

Shielding Options:

Add or remove shielding layers to suit the electromagnetic environment of your application.

Specialized Jackets & Layers:

Integrate outdoor-rated jackets, fire-resistant layers, or armoring to withstand harsh weather conditions, fire hazards, or mechanical stresses.